When was the last time you saw a road sign? Almost every time you are on the road, isn’t it.

A stop sign at the intersection, a speed limit reminder, maybe a street name as you gave directions to someone. We see hundreds of them every day, but this time, you actually noticed the road sign.

You see printing industry is constantly evolving, and as a savvy print service provider like you, such a profitable niche with steady demand and minimal competition represents road sign printing represents worth grabbing opportunity.

No matter if you run a web to print storefront or manage a large-format printing operation, starting road sign printing could open a valuable revenue stream for your business.

In this blog, we will guide you through understanding the road signs, in what type of materials and shapes road signs are created, and everything you need to know regarding this niche. We have also covered the technical requirements that you must look after to scale in this niche.

Table of Contents

What Does Road Signs Printing Mean?

Road signs printing refers to the specialized production of traffic control and informational signage used on streets, highways, and private properties.

Unlike typical signage work, road signs printing must adhere to strict regulatory standards set by transportation authorities, including specific dimensions, materials, reflectivity grades, and color specifications outlined in the Manual on Uniform Traffic Control Devices (MUTCD).

This niche encompasses everything from standard regulatory signs like stop signs and speed limits to custom street signs for residential developments, parking lot directional signs, and private road signage.

For print service providers, it represents a unique intersection of compliance-driven production and customization opportunities.

Is Road Sign Printing a Good Idea?

Absolutely yes, and here’s why this niche deserves your attention.

The road signs market offers remarkable stability because it’s driven by both regulatory requirements and infrastructure development. According to Wise Guy Reports this market it is estimated to scale a growth at a CAGR of 4.1%, i.e., going from US$ 4.65 billion in 2024 to US$ 7.2 billion by 2035.

Road signs are not discretionary. Municipalities and road authorities must comply with safety standards, making replacements or upgrades a consistent requirement.

Unlike promotional printing that fluctuates with marketing budgets, road signs are non-negotiable safety requirements.

The profit margins in road sign printing are typically higher than standard large-format printing work because of the specialized knowledge and compliance requirements involved. Many general printers avoid this niche due to its technical demands, which means less competition for those who invest in understanding the requirements.

Additionally, road sign customers tend to place repeat orders. Once you become a trusted supplier for a municipality or property management company, you’ll likely see recurring business.

From a business perspective, offering road signs printing also positions you as a comprehensive solution provider.

And the best part, the same equipment and expertise used for road sign printing can be applied for various printing needs like parking signs, facility wayfinding, construction site signage, and safety signs, multiplying your revenue opportunities within the same operational framework.

Understanding the Road Signage Printing Market Before Diving In

Road signs are really the unsung heroes in the large format printing market. They guide people, signal safety and bring orders to everything from highways to housing communities. And behind every sign is a specialized printing process that most people never think about… but every print service provider (PSP) should.

Why?

Because road sign printing is becoming one of the fastest-growing, highest-margin niches in large-format printing.

For years, government bodies dominated the demand for standard traffic signs. But that’s changing.

Today, private communities, corporate campuses, logistics hubs, industrial parks, resorts, universities, and event organizers all need durable, branded, custom road signs, and they want them fast.

Understanding Road Signs and Meanings: The Four Main Categories

Every road sign is more than a directive; it’s a safety communication tool.

In cities and highways where precision and clarity are non-negotiable, the quality of print directly affects visibility, compliance, and durability.

From standard street signs to custom road signs for private communities and campuses, governments and infrastructure agencies need partners who understand not only print quality but also the materials, coatings, and standards behind compliant signage printing.

Before diving into production, it’s essential to understand what you’ll actually be printing. Road signs fall into four primary categories, each with distinct purposes and design requirements.

1. Regulatory Road Signs

These signs are the rule-makers of the road. They include familiar stop signs, speed limit notices, and no parking zones. When you are printing regulatory signs, accuracy is not important; it is mandatory.

We often might have noticed that these regulatory road signs are in red color.

As these signs enforce laws, every detail matters and has to be clearly visible to the people. Red color has often been associated with mandatory instructions, which makes it the right choice for regulatory road signs.

Regulatory road signs need to have premium reflective sheeting because they must be visible 24/7, and they are typically permanent installations. Aluminum makes the perfect choice for such road signs as they are sturdy and have a lifespan of over 10 years.

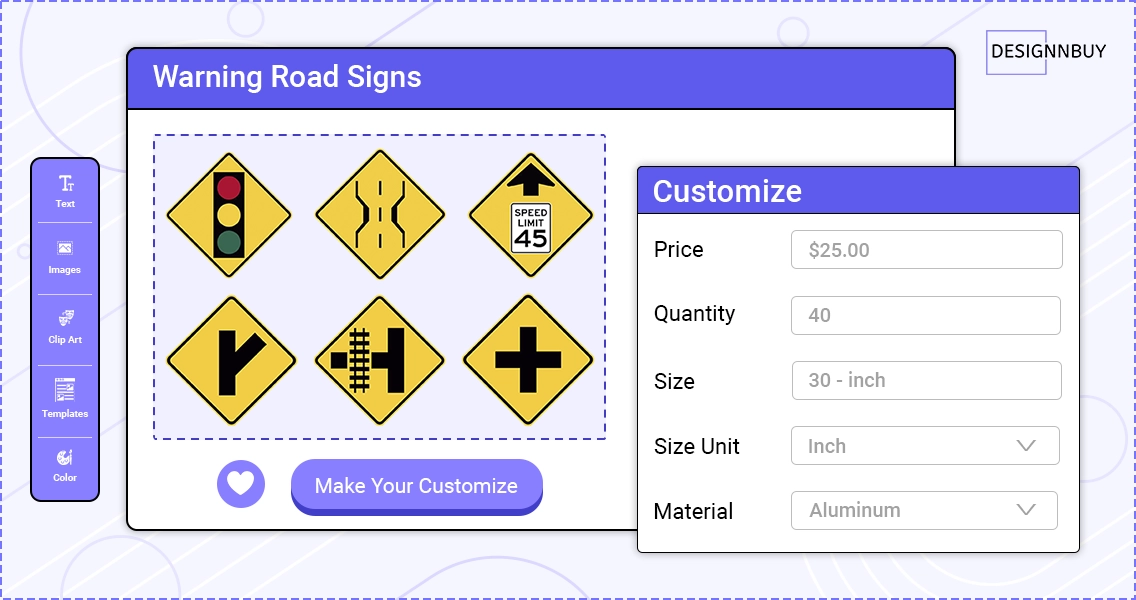

2. Warning Road Signs

Warning road signs are pretty self-explanatory. They are the signs that warn, in fact, alert the citizens about a curved road ahead, pedestrian crossing, or even slippery roads.

These signs need to grab attention quickly, which is why they need to have a distinctive shape and bright color. The choice of color is not for aesthetics; it is more about cognitive psychology.

Yellow is proven to catch peripheral vision without causing panic (like red does). Whereas diamond shape is unique and tilted, making it stand out from regular rectangular signs.

These signs often need the highest-grade reflectivity like Diamond Grade Type XI because they warn citizens of dangers that could cause accidents.

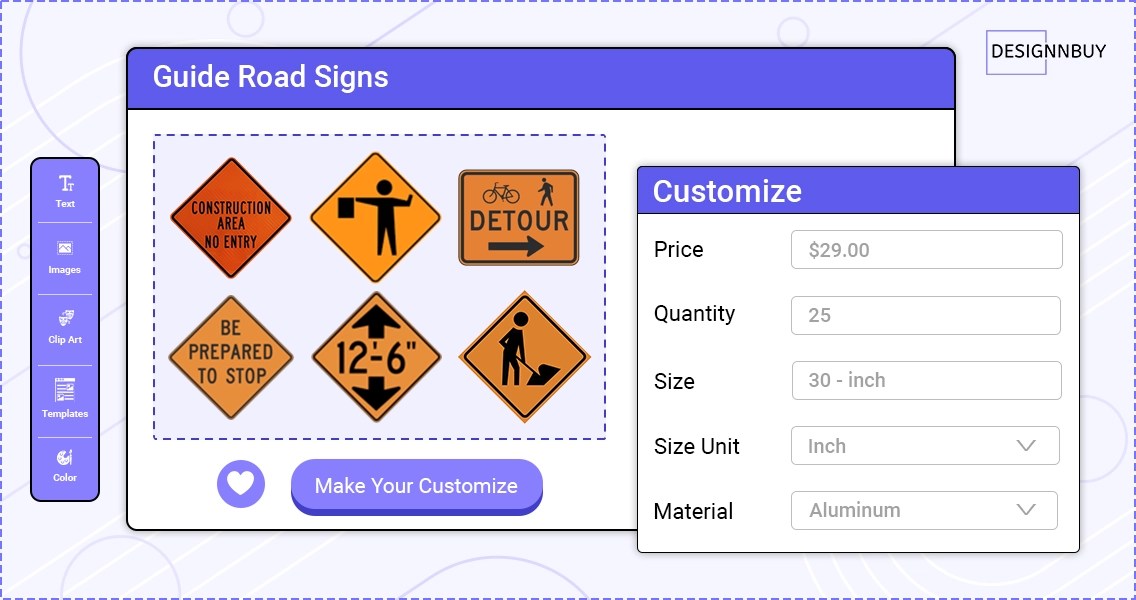

3. Guide Road Signs

Guide road signs are to help people get where they are going. Street name signs and highway route signs and green signs that show distance to major cities fall into this category.

Unlike a warning sign on a rural curve that might be seen occasionally, guide road signs are in high-traffic areas. They fade faster from constant UV exposure and need frequent cleaning or replacement.

It is okay for these signs to have lower reflective grades, but they need to withstand superior weather resistance and constant UV exposure protection.

4. Construction Road signs

Construction road signs are like the temporary workers of the signage printing world. Their main aim is to alert people about any ongoing construction or maintenance work.

We often find these orange signs in work zones, detour markers, and lane disclosure. They typically have shorter lifespans, but they must stand up to harsh conditions of the construction work during their service period.

Aluminum has always been a top choice when it comes to road signage printing. But now, these sign users have turned to corrugated plastic due to their cost effectiveness since they are temporary. However, the ink coating quality cannot be compromised in these terms.

Shape | Common Color(s) | Meaning / Usage |

Octagon | Red | Exclusively used for STOP signs, signaling drivers to halt completely. |

Triangle (Point Down) | Red & White | Indicates YIELD or “Give Way”, instructs drivers to slow and give right-of-way. |

Circle | Red / Blue / White | Used for regulatory or prohibition signs (e.g., speed limits, no parking). |

Rectangle (Vertical/ Horizontal) | White / Blue / Green | Denotes information or guidance, used for street names, route directions, and service info. |

Diamond | Yellow / Orange | Represents warnings, caution signs for curves, crossings, or road conditions. |

Pentagon | Fluorescent Yellow-Green | Marks school zones or pedestrian crossings for heightened safety awareness. |

Trapezoid | Brown / Green | Used for recreational, cultural, or tourist information signs. |

Choosing the Right Materials for Long-Lasting Road Signs

Road signs are typically manufactured using industrial-grade substrates that can withstand harsh outdoor environments, high UV exposure, and constant wear.

- The most common base material is aluminum, mainly preferred for its durability, rust-resistance, lightweight nature, and recyclability.

- Many municipalities and commercial facilities also use aluminum composite panels (ACP) for a more cost-efficient yet rigid alternative.

- For temporary signage or construction signage, coroplast (corrugated plastic) and PVC sheets are widely used due to their light weight and easy printability.

To enhance longevity and visibility, printers layer these substrates with specialized coatings and finishes, such as:

- Reflective sheets (engineer-grade, high-intensity prismatic, diamond-grade) for day/night visibility

- UV-cured inks that prevent fading under prolonged sunlight

- Weatherproof laminates that repel moisture, dirt, and scratches

- Anti-graffiti coatings to resist vandalism and make cleaning easier

- Matte or gloss protective films for surface durability and finish control

Many PSPs also add laminates, including gloss or matte protective films, to extend outdoor life by preventing moisture penetration, color degradation, and surface abrasions.

With DesignNBuy’s large-fromat printing customization capabilities, you can streamline these materials and coatings that are selected during ordering. This ensures every custom road sign is not only compliant and high quality but also optimized for long-term performance.

Why Choosing the Right Web to Print Technology Matters for Print Providers?

Managing large-format printing business is not easy. Juggling with multiple road sign orders, each has different dimensions, materials, reflective grades, and compliance requirements.

One customer wants to edit their design layout because they could not check their printing design in real-time. On the other hand, one client gave you a blurry design file, which when printed was a disaster.

Loss of time, money, materials, and tons of rework? Isn’t it.

This is why the choice of the right large format to print software is crucial for your web to print business.

Instead of getting stuck in manual, repetitive tasks, getting a powerful solution allows you to automate the entire journey, from design personalization to order submission to prepress. Your customers can configure road signs, pick substrates, choose reflective films, personalize layouts, and submit clean, print-ready files without relying on your team for every minor change.

That means fewer redesigns, faster approvals, and zero ambiguity in what goes to production.

This is what you get from DesignNBuy’s sign design software. You can give your customers a unified and efficient workflow that supports high-volume custom orders without overwhelming your staff.

For print providers aiming to scale their road sign vertically, the right technology doesn’t just solve operational headaches; it reduces errors, boosts margins, elevates customer satisfaction, and builds a more predictable, scalable business model.

Who Buys Custom Road Signs and Why It Matters Your Print Business?

Understanding who actually buys custom road signs can completely shift how a print business positions this niche. This is not a market driven by one-time shoppers. It is built on organizations that need reliable, durable, and compliant signage across multiple locations and over long timelines.

- Private communities and homeowners’ associations are a prime example. As neighborhoods grow, renovate, or enforce traffic rules, they constantly need new wayfinding signs, speed limit markers, parking instructions, and branded entrance boards. A single community can generate repeat orders for years, especially as signs fade, regulations change, or new development phases open.

- Corporate campuses are another strong buyer segment. Large offices, tech parks, warehouses, and logistics hubs rely on consistent directional signs, parking lot graphics, and safety signage to move employees and visitors efficiently. These clients expect professional-grade quality and uniform branding, which creates room for higher pricing and bundled services.

- Event venues, stadiums, fairgrounds, and recreational parks also contribute to rising demand. They often require temporary but professional-looking traffic and crowd-control signage that needs fast turnaround and clean execution. Printers who can deliver quickly, in bulk, and with consistent quality find themselves becoming long-term partners rather than one-time vendors.

What ties all these audiences together is a need for durability, clarity, and customization. They value materials that last, reflective finishes that improve visibility, and designs that align with their brand or safety standards.

More importantly, most of these clients come back for updates, replacements, and expansions. For printers, recognizing this buyer mix is the key to turning road signs into a reliable, recurring revenue stream rather than just an occasional add-on service.

The Road Sign Printing Process: What to Look After & Why It’s Different from Other Large-Format Printing

As road-sign printing becomes a high-velocity niche, many PSPs still struggle with workflow inefficiencies, customization bottlenecks, and quality-control gaps. These challenges directly impact delivery timelines and profitability, especially when clients expect fast, precise, regulation-compliant signage.

1. Start with the Right Substrate

When you’re printing road signs, the base material matters more than in typical large-format work. Instead of lightweight PVC or fabric, most job specs call for aluminum sheets (or aluminum-composite panels).

Why? Because durability counts. These signs must handle rain, wind, sunlight, and years of service. Standard prints don’t face that level of environmental stress.

2. Apply Reflective or High-Visibility Layers

One of the biggest differentiators: road signs often need retro-reflective sheeting. This isn’t a “nice bonus”, for many clients; it’s essential for visibility at night or in low-light conditions.

Regular large-format printing seldom demands these specs. For road signage, you’ll need to factor in the cost, the supplier, the correct grade (Engineering, High-Intensity, Diamond), and proper application technique.

3. Precision Printing of Graphics and Lettering

In this vertical, you’re not just printing pretty visuals. You’re printing for readability, safety, and compliance. That means:

- Fonts that meet readability standards at distance

- Colors matching regulation or brand specs

- Ink adhesion that resists weathering, UV-fade, abrasion

Unlike typical jobs (posters, banners) where the lifespan might be months, here it’s years. The risk of getting it wrong is higher, and so is the reward when you nail it.

4. Add Protective Laminate and Finishing Coatings

Because these signs are outdoors for years, you’ll often apply protective laminates or coatings: UV-protection, abrasion-resistant layers, anti-graffiti finishes, weatherproof sealing.

This step becomes a value proposition, not just a manufacturing step. You can offer tiers: basic finish vs. premium finish, and that opens upsell opportunities.

5. Fabrication, Mounting Preparation & Finishing Tasks

Once the sign is printed, there’s fabrication: CNC routing or shearing, drilling/punching mounting holes, corner rounding, edge finishing. Unlike typical posters or retail prints, the sign has to be ready for installation.

Missing a drilling pattern or leaving a sharp corner can undermine safety, or even invalidate a job spec.

6. Final Inspection and Quality Assurance

This is where process intelligence pays off. Before shipping, you check:

- Reflectivity grade (if required)

- Color accuracy and fade risk

- Adhesion of laminates/coatings

- Correct mounting hole placement

- Material integrity (no warping or defects)

A sign might sit outdoors for a decade; the risk of failure is real. If you guarantee your work, you had better inspect it.

Why This Workflow Stands Apart from Typical Large-Format Printing

- Lifespan matters: Road signs need to last years, not months.

- Compliance matters: Visibility, readability, materials, installation, all face higher specs.

- Material and finishing cost are higher, but so is the margin.

- Installation readiness: It’s not just printing, it’s production + fabrication + installation readiness.

- Upsell potential: Protective coatings, premium materials, high-reflectivity sheeting; all are additional revenue streams.

How to Enter the Custom Road Sign Printing Market Niche?

Entering the custom road sign printing space doesn’t require a complete overhaul of your business, but it does demand a focused, strategic approach. This niche rewards printers who understand materials, compliance, and production workflows, so laying the right foundation is essential.

1. Start with a capability audit

Check if your equipment can handle rigid substrates. UV flatbeds, CNC routers, or rigid cutters give you a head start. If not, evaluate whether upgrading fits your growth potential.

2. Choose certified, compliant materials

Partner with suppliers who offer certified aluminum, ACP sheets, reflective films, and approved inks. Government and municipal buyers often require documentation.

3. Understand regulations before you produce

Learn which standards apply in your region. MUTCD in the US, EN standards in Europe, or local codes elsewhere. Understanding rules builds credibility with high-value clients.

4. Adopt the right sign designer software

Custom road sign jobs need template-driven design, reflectivity options, and compliance checks. Specialized sign designer software from DesignNBuy eliminate back-and-forth revisions and reduce production errors.

5. Prepare for fabrication and installation needs

Routing, drilling, corner finishing, and installation prep are part of the workflow. You can either manage this in-house or collaborate with a metal fabricator.

6. Build relationships with recurring buyers

HOAs, corporate campuses, construction companies, and facilities managers order frequently. Delivering accurate, compliant signs for the first time naturally leads to repeat business.

Pain Points Faced by PSPs and How Sign Design Software Can Solve Them?

As road-sign printing becomes a high-velocity niche, many PSPs still struggle with workflow inefficiencies, customization of bottlenecks, and quality-control gaps. These challenges directly impact delivery timelines and profitability, especially when clients expect fast, precise, regulation-compliant signage.

1. Constant Artwork Revisions

Printers often lose hours fixing low-resolution uploads and correcting design mistakes from clients. A sign design system with guided templates and real-time proofs eliminates back-and-forth and ensures print-ready files from the start.

2. Handling Compliance and Specification Errors

Incorrect fonts, colors, or reflective requirements can delay jobs or lead to costly reprints. Software that includes pre-built regulatory templates keeps every sign aligned with regional standards, reducing risk and rework.

3. Slow Order Processing and Bottlenecks

Manual quoting, artwork approval, and job setup stretch production timelines. A streamlined web to print workflow automates these steps, so print teams can focus on output instead of admin tasks.

4. Inconsistent Branding Across Multiple Sign Types

Corporate and community clients expect uniformity across wayfinding, safety, and directional signs. Centralized design controls within a digital design tool to maintain consistency across every product variant.

5. Difficulty Scaling High-Volume or Repeat Orders

PSPs often struggle when customers need multiple signs or frequent replacements. With configurable product templates and automated job submission, platforms like DesignNBuy help print service providers scale without adding operational overhead.

Bottom Line

The road signs printing niche offers print service providers like a rare combination of stable demand, higher margins, and predictable revenue cycles.

As infrastructure investment grows globally and smart city initiatives expand, the market for professional road sign printing and custom street signs continues to strengthen.

Success in this niche requires three elements: technical expertise in materials and compliance, the right production equipment, and efficient order management systems.

While the barriers to entry are real, with the right robust road sign printing software From DesignNBuy, equipment investment, regulatory knowledge and material certification, success is achievable for determined providers. For print businesses ready to specialize, the opportunity is clear.

The road ahead is well-marked, and with DesignNBuy’s right web to print solution, that facilitates businesses with manual order-taking to an automated, scalable operation that handles everything efficiently.

Ready to Enter the Road Signage Printing Market?

Leverage the power of customization with web to print sign design software